Start Here

With The wema.digital newsletter

James and Sarah are both central figures within their organisations. James leads production for a well-established manufacturing company, while Sarah oversees operations at a mid-sized precision engineering firm.

For years, both built their reputations on reliability and efficiency. Their processes were robust, their teams confident, and their performance consistent. Operational excellence wasn’t a goal, it was the standard.

Then, three months ago, everything began to shift. They started working late most nights, trying to keep projects on schedule. Production and service planning that once took a few days now dragged on for two weeks or more. What were once tightly aligned operations, focused on a single outcome, began to drift in different directions, creating confusion, duplicated effort, and an unbearable sense of lost control.

The pressure was undeniable:

Production planning stretched to two weeks, even for simple schedules.

Project coordination relied on endless email threads and manual follow-ups.

Teams operated with outdated or conflicting information.

Minor delays quickly escalated into significant project disruptions.

Quality systems and project planning became increasingly disconnected.

Communication channels no longer matched how teams actually worked.

Training programmes became reactive, addressing issues only after they occurred.

Parallel operations designed for one goal began to diverge in multiple directions.

James and Sarah could see it clearly. Their once-reliable systems were no longer serving them. The methods that had once given them control were now creating friction. To move forward, they needed to rethink not only their tools but also the way their organisations worked, aligning people, systems, and processes for the next stage of growth.

Most middle managers, at some point in their careers, experience a situation much like James and Sarah’s. The symptoms may vary, delayed projects, misaligned teams, or processes that no longer scale, but the underlying challenge is the same.

systems that once worked begin to hold the organisation back

If you recognise some of these signs within your own operation, it’s not a signal to blame the process, it’s a signal to act. Identifying the root cause early and implementing a structured, semi or fully data-driven response can turn the tide before inefficiencies become the new culture.

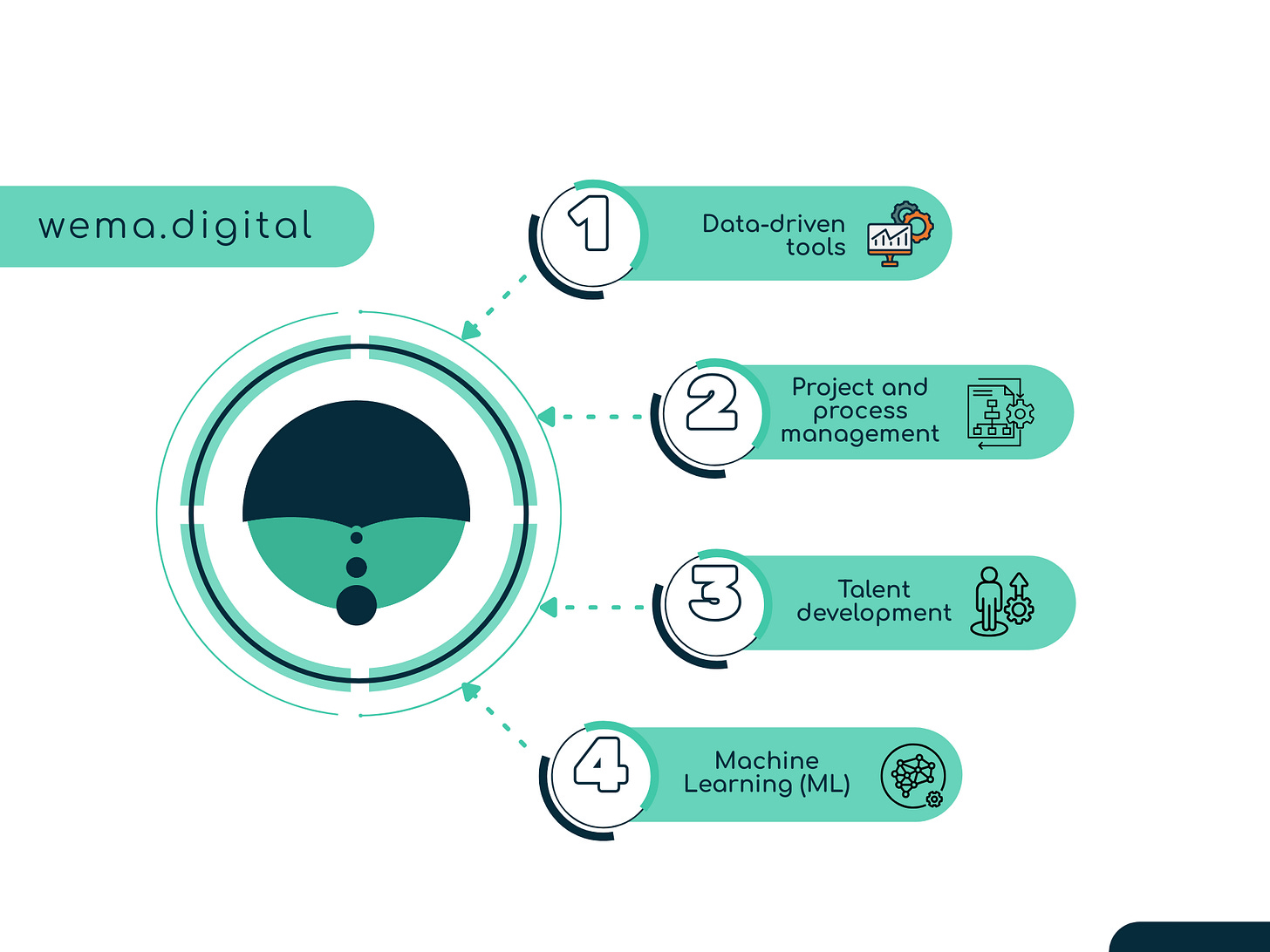

This is exactly what we’re addressing at wema.digital, helping technical and engineering teams find their way with emerging digital tools. With the right partner and platform, it’s possible to make a measurable difference. Restoring clarity, improving collaboration, and transforming complexity into sustainable performance.